- Power, Air, Hand Tools, Airline Equipment & Accessories

- Building, Tiling Tools & Accessories

- Materials Handling

- Power & Air Tools

- Lifting & Pulling

- Health & Safety

- Air Tools

- Footwear & Clothing

- Compressed Air Line Equipment

- Tool Boxes, Mechanic's Tool Chests, Cabinets & Storage

- Power Tool Accessories

- Measuring Tools & Measuring Equipment

- Storage

- Hand Tools & Accessories

- Generators

- Painting

- Outdoor, Gardening & Leisure

- Boating Accessories

- Garden & Underwater Lights

- Fuel Cans

- Vehicle Shelters & Sheds

- Gardening Tools & Safety

- Water Gardening, Ponds, Fountains & Accessories

- Fountain Sets & Water Features

- Fountain, Pond, Waterfall, Water Gardening & Aquarium Pumps

- Garden & Underwater Lights

- Pond Water Treatment & Chemicals

- Pond Filtration

- Pond Aeration

- Pond Accessories

- Fountain Nozzles

- Pond Vacuum Cleaners& Maintenance

- Preformed Ponds PE/Organic & Pond Liners

- UVC Clarifiers, UV Bulbs & Algae Destroyers

- Pond Surface Skimmers

- Water Garden & Pond Decoration

- Hose, Watering & Accessories

- BBQ, Stove & Oven

- Multi-Tools

- Indoor Aquatic Equipment & Accessories

- Pressure Washers

- Powerpacks

- Pumps & Accessories

- Trolleys & Wheelbarrows

- Trailer Accessories, Lights, Recovering, Towing & Winches

- Security

- Generators

- Camping & Caravanning

- Chainsaw Sharpeners

- Solar Products

- Home & Garden Thermometers, Hygrometers

- Motorbike & Bicycle Tools & Accessories

- Special Offers

- Fluid Handling & Transfer

- Cold Water Tanks

- Electric & Manual Fuel Pumps

- Lifting Stations

- Electric Surface Centrifugal Stainless Steel & Cast Iron Pumps Open Impeller

- Pump Controllers & Spare Parts

- Spare Parts for Pumps

- Hot Water Circulators

- Variable Speed Water Booster Sets & Drives

- Membrane Pressure & Expansion Vessels

- Accessories for Pumps

- Float, Flow Switches, Flow Meters & Level Controllers

- Cold Water Tanks

- Non-Return Valves

- Suction Strainers

- Flexible Hoses, Fittings & Pump Accessories

- Pressure Switches

- Sacrificial Anode for UMBRA Sub Pumps

- Pressure, Vacuum Gauges & Syphons

- Motor Run Capacitors

- Brass Fittings

- Sealing Products

- Plastic Pipe Fittings

- Irrigation Products

- Consumables

- Flexible Impeller Pumps & Spare Parts

- In Line Vertical Single Stage Pumps

- Single & Twin Shower Pumps

- Horizontal Multistage Pumps

- Petrol Driven Pumps

- Jet Self Priming Pumps

- Submersible Borehole Pumps & Electric Motors

- Specialty Pumps

- Electric Surface Centrifugal Pumps

- Peripheral Pumps

- Low Voltage Surface/Submersible Pumps

- Domestic Water Booster Sets

- Vertical Surface Multistage Pumps

- Fire Fighting Sets

- Swimming Pool Pumps

- Submersible Drainage/Sewage Pumps

- Centrifugal Bare-Shaft Pumps

- Electric Control Panels & Accessories

- Fountain, Pond, Waterfall, Water Gardening & Aquarium Pumps

- Water Conditioning & Filtration

- Welding, Soldering, Accessories & Consumables

- Industrial Equipment

- Flange & Manhole Boiler Gaskets

- Pneumatic ON/OFF Control Valves with Piston Actuator

- Cathodic Protection / Magnesium Anodes

- Pipeline Fittings & Tools

- Consumables

- Compressed Air Taps

- Plate Heat Exchangers

- Flexible Hoses for Steam, Gas & Cold / Hot Water

- Air - Water Eliminators for Steam, Water & Air Systems

- Vacuum Breakers

- Pressure Switches

- Pipeline Strainers

- Electric / Pneumatic / Manual Control Valves & Actuators

- Industrial Steel / Brass Wire Brushes

- Sight Glasses, Sight Checkers & Spare Parts

- Heating Oil & Gas Filters

- Extendable Aluminium Tubes

- Thermostats

- Non Return Valves

- Thermometers & Pressure Gauges

- Refractory, Thermal Insulation & High Temperature Material

- Pressure Relief Valves

- Oil & Gas Firing Burners

- Pressure Operated Condensate Pumps

- Sealing, Lubricating, Greasing & Cleaning

- Special Equipment for Steam

- Isolation Valves

- Air and Gas Float Traps

- Liquid Level Indicators, Reflex Glasses, Glass Tubes, Accessories & Spare Parts

- Electric Solenoid Valves & Coils

- Steam Traps

- Steel Immersion Heating Elements & Heating Cables

- Hot Water Storage Tanks

- Humidity Separators

- Cold & Hot Water Meters

- Oil & Gas Burner Spare Parts

- Pressure Reducing Valves (Steam, Compressed Air & Liquids) & Spare Parts

- Float, Flow Switches, Flow Meters & Level Controllers

- Electric Motors, Transmission Couplings & Pullies

- PTFE (Teflon) Products

- Water Saving Jet-Spray Guns

- Storage, Ladders & Material Handling

- Electrical and Electronics

- Cable Management

- Flood & Work Lights

- Cable Reel, Cable Extension & Plug

- Solar Lights

- Magnifying Lamps

- Powerpacks

- Electrical Tester & Multimeter

- Electrician Hand Tools & Accessories

- Electronic Thermometers & Humidity Meters

- Soldering Kits & Gas Torches

- Electric Control Panels & Accessories

- Electrical Fittings, Terminals and Fuse Kits

- Motor Run Capacitors

- Cable Insulation

- Battery Chargers/Starters, Booster Cables & Testers

- Power Inverters

- Inspection Lamps, Torches & Search Lights

- Screws, Nails, Fixings, Fastenings, Washers & O'Rings

- Automotive & Garage Equipment

- Pressure Washers

- Axle Stands

- High Temperature Paints

- Fuel Cans

- Mechanics’ Seats & Car Creepers

- Engine Workshop Cranes

- Vehicle Shelters & Sheds

- Parts Washers & Washing Fluids

- Air Compressors & Air Line Equipment

- Power & Air Tools

- Body Repair Kits

- Barrel, Fuel Transfer Pumps, Taps & Accessories

- Multi-Purpose Vices & Anvils

- Sandblasters, Blast Mediums, Accessories & Spares

- Car Care Products & Accessories

- Tool Boxes, Mechanics' Tool Chests, Cabinets & Storage

- Battery Chargers/Starters, Booster Cables & Testers

- Motorcycle Dollies, Stands & Hydraulic Lifts

- Workshop Consumables & Safety

- Hydraulic Lifts

- Drill & Arbor Presses

- Blast Mediums

- Workbenches, Tool/Parts Trolleys

- Hand Tools & Accessories

- Garage Accessories

- Welders, Accessories & Consumables

- Trailer Accessories, Lights, Recovering & Towing

- Chain Blocks & Winches

- DIY, Semi & Professional Jacks

- Garage Testing, Diagnostic & Measuring Instruments

- Woodworking & Metalworking

- Heating, Plumbing & Ventilation

- Pressure, Vacuum Gauges, Thermometers & Syphons

- Cold Water Tanks

- Non-Return Valves

- Electric Instant Water Heaters

- Thermostats & Temperature Controllers

- Water Treatment, Detergents & Chemicals

- Water Air Separators

- Pipeline Equipment & Acessories

- Extendable Aluminium Tubes

- Pressure & Flow Switches

- Electric Fan, Oil, Infrared / Gas Heaters, Air Purifiers & Air Coolers

- Plastic Pipe Fittings

- Brass Fittings

- Hot Water Storage Tanks

- Valves & Faucets

- Cold & Hot Water Meters

- Sealing Products

- Pressure Reducing & Feed Valves

- Plumbing Tools & Accessories

- Ventilators & Air Movers

- Cast Iron Stoves, Maintenance & Accessories

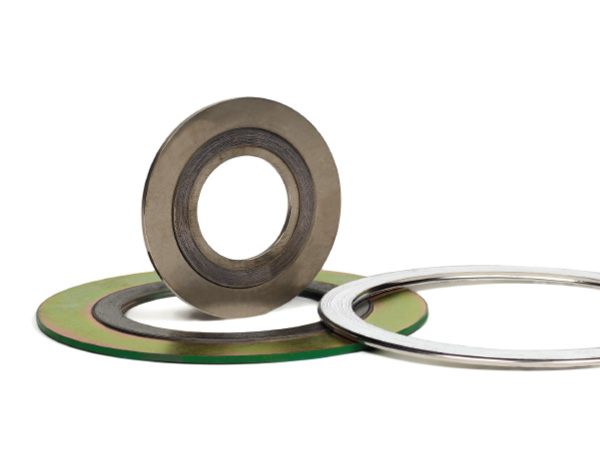

Texpack Spirometallic Wound Gaskets, Sizes DN15 to DN150

Call for Price

The spiral-wound gaskets are made of metal tape with a specially shaped profile coupled with a filler tape (graphite), both uniformly wound with constant winding tension. The unique metal profile has an elastic action that guarantees a perfect seal under all fluctuating temperature and pressure conditions. They can be assembled to a centring ring that may be external, internal or both. The rings are used for precise purpose: the inner ring has an anti-turbulence function, since it usually has an internal diameter equal to the internal diameter of the flange. It prevents the deposition of material in the gap between flanges and is normally constructed with the same material as the spiral, so it protects it against corrosion and eliminates any flange erosion. The outer ring serves as a centering device between the bolts, prevents lateral expansion of the seal and serves as a reference shim for correct assembly.

Applications

Oil refineries, chemical industries, plants for the production and transformation of steam and power stations.

Characteristics:

Maximum operating temperature: -200 C to 550 C

Operating pressure at 500 C: 186kg/cm2

Available sizes: DN15 up to DN150

You must be logged in to post a review.

Call for Price

Call for Price

Reviews

There are no reviews yet.